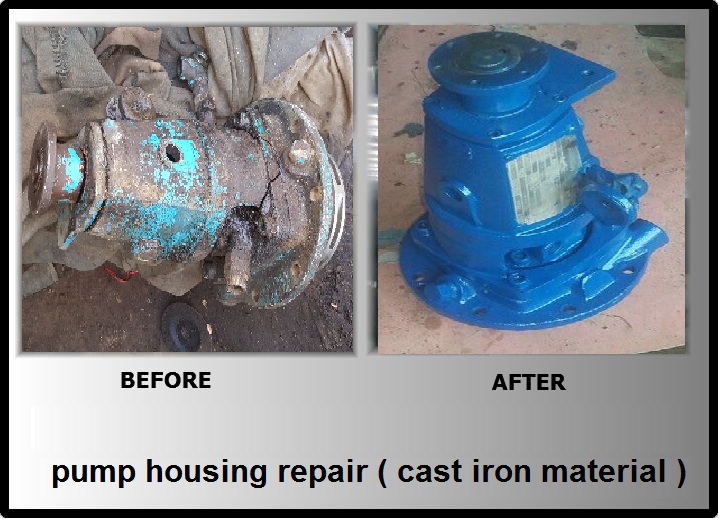

Exposure to water especially waste water in the long run, causes corrosion in the inner body of the pump, which affects its efficiency and may lead to its failure completely, and as is customary, pumps used in drinking water and sewage stations are expensive pumps.

That is why EPCCO has made a plan to maintain and repair these pumps and return them as new by following international maintenance standards and by highly trained workers to do so. Which reduces the sums paid by Egypt state to import such pumps.

Repairing steps:

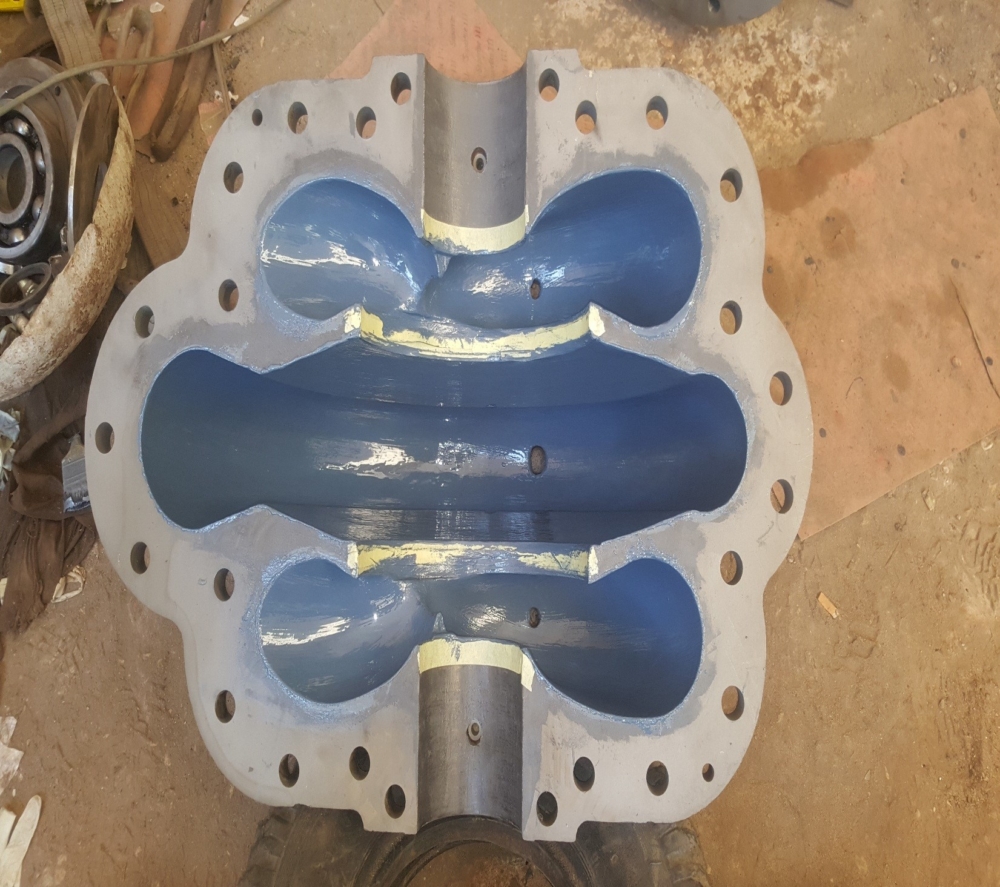

- Make a blasting to all the parts of the pump to detect cracks and erosions.

- Make DPT on the broken parts to determine the location and dimensions of cracks.

- Weld the whole broken part using a special electrode to avoid the following:

- Hydrogen waste

- Martinets transformation

- Carbide precipitation

- Change all damaged spare parts

- Use a cold welding technique using unique polymer system products to rebuild all the corrosions in the pump body then Apply of a polymeric coating system that could be handle with the process water with specific operation condition even in presence of small solid particles (Sludge) with total coating thickness of 500 – 600 microns as a double coat to protect from erosion & corrosion.